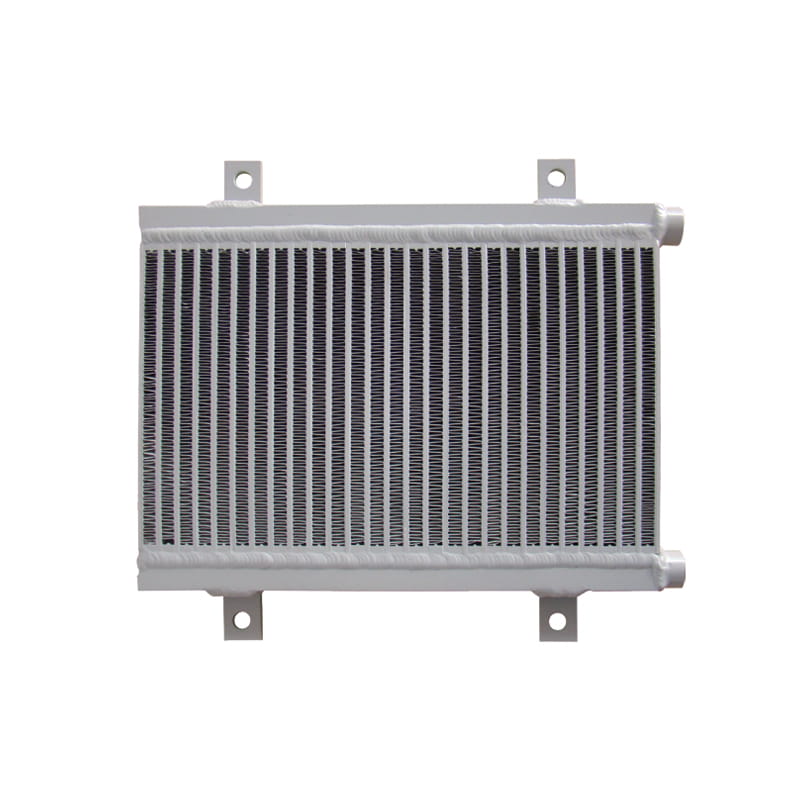

Dirt, debris, and agricultural residues can accumulate on the surface of heat exchangers, reducing their efficiency. Regular cleaning with compressed air, water, or specialized cleaning solutions is necessary to remove these contaminants. Pay close attention to fins, tubes, and other components to ensure unrestricted airflow and heat transfer.

Perform visual inspections of the heat exchanger regularly to identify any signs of damage, corrosion, or leaks. Check for bent fins, cracks in tubes, or loose connections. Early detection of issues allows for prompt repairs, preventing further damage and downtime.

Monitor the quality and level of coolant, hydraulic fluid, or other fluids circulating through the heat exchanger. Replace fluids at recommended intervals to maintain proper viscosity, thermal conductivity, and corrosion protection. Contaminated or degraded fluids can impair heat transfer efficiency and damage the heat exchanger components.

Periodically conduct pressure tests to assess the integrity of the heat exchanger and its connections. This helps identify any leaks or weaknesses in the system. Address any leaks promptly to prevent fluid loss and maintain optimal performance.

Bent or damaged fins can obstruct airflow and reduce heat transfer efficiency. Use a fin comb or appropriate tools to straighten bent fins carefully. Ensure fins are aligned properly to maximize heat exchange surface area.

Apply corrosion inhibitors or coatings to protect the heat exchanger from corrosion, especially in corrosive agricultural environments or when using water-based fluids. Inspect protective coatings regularly for signs of wear or damage, and reapply as necessary.

If the heat exchanger is equipped with a fan, inspect it regularly for proper operation. Clean fan blades and motor housing to prevent buildup of dirt and debris. Ensure fan belts are properly tensioned and replace them if worn or damaged.

For more complex maintenance tasks or repairs, consult with a qualified technician or service provider specializing in agricultural machinery. They can perform thorough inspections, diagnostics, and repairs to ensure the heat exchanger operates at peak efficiency.

By following these maintenance procedures diligently, agricultural machinery heat exchangers can remain in optimal condition, contributing to reliable performance, efficiency, and longevity of the equipment.

English

English русский

русский