Liquid cold plates is a cooling device that uses liquid circulation to absorb and conduct heat. It is widely used in electronic equipment with high power density and high heat load. Compared with traditional air-cooled systems, liquid-cooled heat sinks have higher heat conduction efficiency and more uniform temperature control capabilities. They are an important means to achieve efficient heat dissipation in the fields of electronics, communications, computers and new energy.

Liquid cold plates introduce cooling liquids (such as water, ethylene glycol solution, etc.) into the equipment by arranging liquid channels in the plate. Driven by a liquid pump, the cooling liquid flows along the preset channels to absorb the heat generated by electronic components or heat sources. Subsequently, the liquid that takes away the heat is transported to an external radiator or heat exchanger, and by exchanging heat with the external environment, the temperature is reduced and then circulated back to the cold plate to form a complete thermal management system.

Liquid cold plates use the high heat capacity and thermal conductivity of liquids to quickly and efficiently transfer heat from the heat source to the cooling medium. Compared with air-cooled systems, liquid-cooled heat sinks have higher thermal conductivity efficiency and can handle heat sources with higher power density, avoiding performance degradation or damage to electronic equipment due to overheating.

Liquid-cooled systems form a uniform flow of coolant throughout the cold plate, ensuring a more uniform temperature distribution on the surface of the equipment and avoiding local overheating. This uniform temperature control is important for electronic components that require precise temperature management, such as power semiconductors, lasers, etc.

Liquid-cooled heat sink systems are generally quieter than air-cooled systems because they do not require high-speed fans for forced convection heat dissipation. This is particularly beneficial for application scenarios that require a quiet working environment, such as data centers, laboratory equipment, and high-performance computers.

Liquid cold plates can be designed more compactly inside the equipment and take up less space. This allows electronic equipment to reduce the overall size while maintaining high performance, making it possible to design products that are lightweight and compact.

As the server density and power consumption of data centers continue to increase, traditional air-cooled systems have been unable to meet the needs of efficient heat dissipation. Liquid-cooled heat sinks ensure that servers maintain a stable temperature during high-performance operation through efficient thermal management, thereby improving the energy efficiency and operational reliability of data centers.

In electric vehicles, batteries and motors generate a lot of heat when working at high power. Liquid cooling heat sinks can effectively manage the heat of these key components, prevent performance degradation or failure caused by overheating, extend battery life, and improve the safety and performance of the entire vehicle.

In supercomputing centers and scientific research institutions, liquid cooling heat sinks are used to dissipate heat for high-performance computers (HPC) and graphics processing units (GPUs). Through efficient liquid cooling systems, these devices can maintain a stable operating temperature when running at high loads, achieving higher computing speeds and efficiency.

5G base stations, satellite communication equipment, and data transmission equipment generate a lot of heat when working at high frequency and high power. Liquid cooling heat sinks ensure the stable operation of these devices through efficient heat dissipation, reducing communication interruptions and equipment damage caused by overheating.

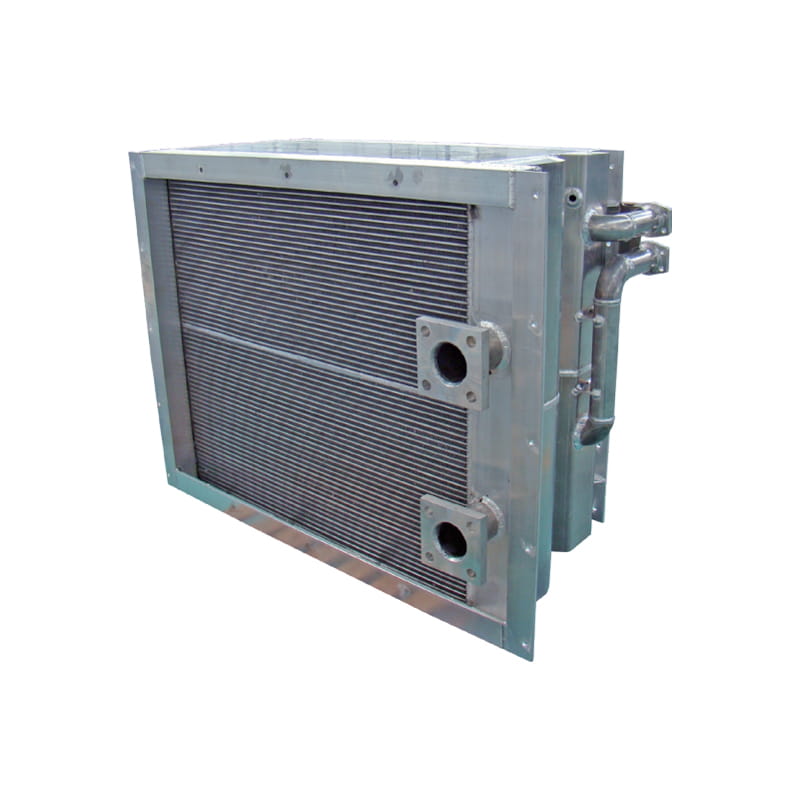

The design of liquid cooling heat sinks needs to consider the layout of liquid channels, the selection of coolant, and the thermal conductivity of materials. Commonly used materials include high thermal conductivity metals such as aluminum and copper to ensure efficient heat conduction. At the same time, the channel design needs to take into account fluid dynamics and heat transfer effects to achieve the best cooling effect. The choice of coolant is also very critical, and it must have good thermal conductivity, low viscosity, and corrosion resistance.

As the power density of electronic devices continues to increase, liquid cooling heat sinks will be used in a wider range of fields. Future development trends include more refined flow channel design, the application of composite materials, and intelligent temperature control technology. At the same time, green environmental protection is also an important direction for the development of liquid cooling technology. Research on non-toxic, degradable coolants and energy-saving liquid cooling systems will help reduce the environmental impact of liquid cooling heat sinks.

As an efficient thermal management solution, liquid cooling heat sinks play an irreplaceable role in modern electronics, communications and new energy fields. With its advantages of efficient heat dissipation, uniform temperature, low noise and space saving, it provides a reliable temperature control method for high power density equipment. With the continuous advancement of technology, liquid cooling heat sinks will show greater potential in more applications, providing strong support for the performance improvement and reliability of electronic equipment.

English

English русский

русский