Liquid cooling plate is a device for efficient heat dissipation, which is widely used in electronic equipment, data centers, automotive industry, aerospace and other fields. With the continuous miniaturization of electronic equipment and the increase in power density, traditional air cooling has been difficult to meet the heat dissipation needs. Liquid cooling plate has become an important technology to solve these challenges due to its excellent thermal management capabilities.

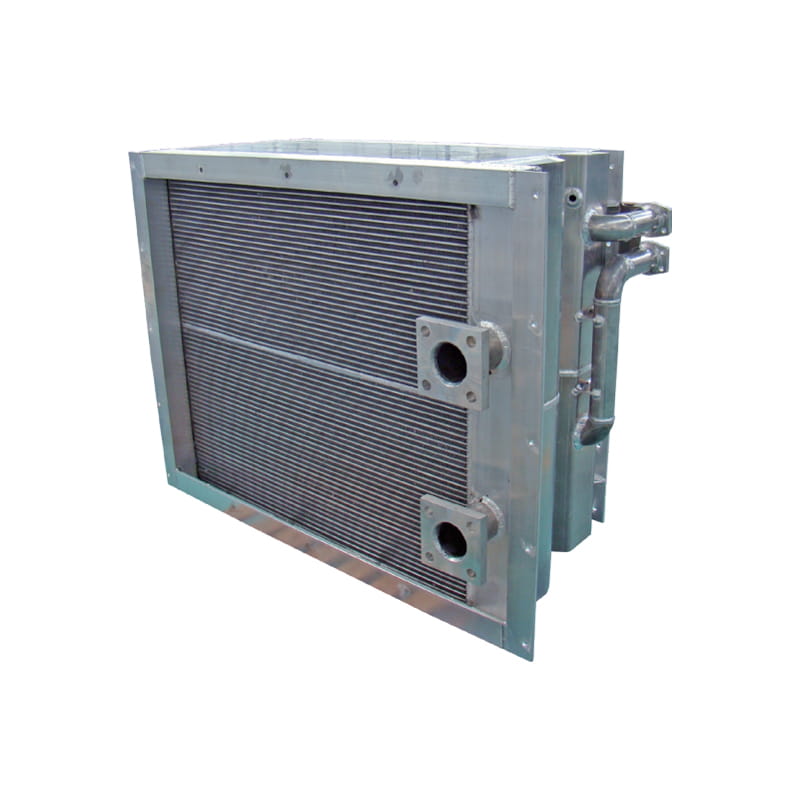

Liquid cooling plate absorbs and takes away the heat from the heat source through liquid circulation. Liquid cooling plate is usually made of materials with excellent thermal conductivity (such as copper or aluminum), and has liquid channels designed inside. The liquid (usually water or coolant) circulates through these channels under the push of a pump, absorbs the heat generated by the heat source into the liquid, and takes it away, thereby effectively reducing the operating temperature of the equipment.

Application field of liquid cooling plate

In high-performance computing (HPC) and servers, processors and graphics cards are heat-intensive, and liquid cooling plates can efficiently dissipate heat to ensure stable operation of equipment under high load.

With the increase in power density of data centers, liquid cooling plate systems provide better heat dissipation solutions for servers, improve energy efficiency, reduce dependence on traditional air cooling systems, and reduce operating costs.

In electric vehicles, batteries and motors generate a lot of heat when working. Liquid cooling plates can accurately control the temperature of these key components, extend their service life, and improve the performance and safety of the vehicle.

In the aerospace field, electronic equipment and power systems work in high-temperature environments. Liquid cooling plate systems provide the necessary thermal management to ensure that the equipment can still operate efficiently under extreme conditions.

Advantages of liquid cooling plates

The thermal conductivity of liquid cooling plates is much better than that of traditional air cooling systems, and can quickly and effectively remove the heat generated by high-power equipment.

The liquid cooling plate system is relatively compact and suitable for installation in space-constrained environments, especially for miniaturized and high-density equipment design.

Since the liquid cooling plate mainly relies on liquid circulation for heat dissipation, the use of fans is reduced, the noise of system operation is reduced, and it is suitable for noise-sensitive environments.

The design of the liquid cooling plate can be customized according to different thermal management requirements and adapt to various complex application scenarios.

With the development of science and technology, the application field of liquid cooling plates will be further expanded, and it will play a more important role in cutting-edge fields such as high-performance computing, 5G communications, and electric vehicles. In the future, liquid cooling plate technology will continue to develop in the direction of more efficiency, more energy-saving, and more intelligent, promoting technological progress and sustainable development in various industries.

As an efficient thermal management solution, liquid cooling plates have demonstrated their unique advantages in many key areas. With the pursuit of higher power density and more stringent heat dissipation requirements, liquid cooling plate technology will become an important pillar for the development of future electronic and electrical equipment.

English

English русский

русский