As technology advances, the need for innovative cooling solutions becomes increasingly urgent. Liquid cold plates have emerged as a transformative technology, redefining how we manage heat in everything from consumer electronics to industrial machinery. By combining efficiency, adaptability, and sustainability, these systems are setting new standards for thermal management in modern applications.

Enhancing Performance Through Precision Engineering

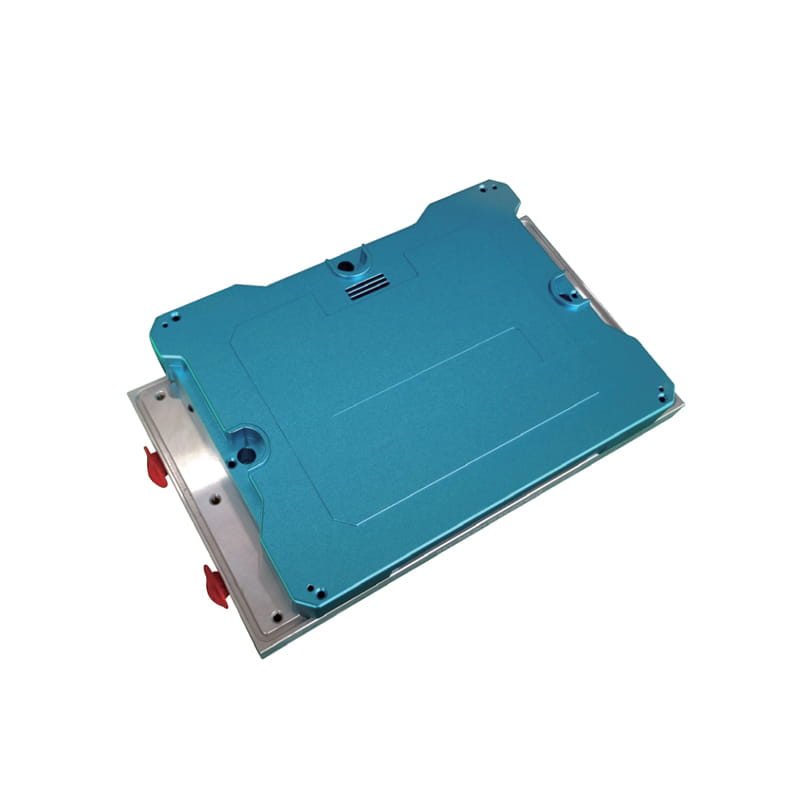

At the heart of liquid cold plates lies precision engineering, which maximizes their ability to transfer heat effectively. The basic principle involves a coolant flowing through channels embedded within a metal plate, absorbing heat from adjacent components before carrying it away to a heat exchanger or radiator. This closed-loop system ensures consistent cooling, even under heavy thermal loads.

The efficiency of liquid cold plates stems from their ability to maintain uniform temperature distribution across surfaces. For example, in high-performance computing (HPC) systems, where multiple processors work simultaneously, uneven cooling can lead to hotspots that degrade performance. Liquid cold plates eliminate this issue by providing targeted cooling exactly where it’s needed, ensuring stable operation and maximizing computational power.

Similarly, in medical imaging equipment like MRI machines, precise temperature control is essential for accurate diagnostics. Liquid cold plates help regulate the thermal output of powerful magnets and electronic components, ensuring consistent image quality and patient safety. Their reliability in mission-critical applications highlights their importance in cutting-edge technologies.

Supporting Sustainability in Energy-Intensive Industries

Beyond their technical prowess, liquid cold plates contribute to sustainability efforts in energy-intensive industries. Traditional air cooling systems often consume vast amounts of electricity due to the constant operation of fans and compressors. In contrast, liquid cooling systems require less energy to achieve the same—or better—results, reducing overall power consumption.

For instance, in data centers, liquid cold plates are being adopted as part of broader initiatives to improve energy efficiency. By lowering cooling-related energy usage, these systems help facilities achieve higher Power Usage Effectiveness (PUE) ratings, a key metric for evaluating sustainability. Additionally, recirculating coolant loops minimize water waste, addressing concerns about resource conservation in large-scale operations.

In renewable energy systems, liquid cold plates support the transition to cleaner technologies. Solar inverters and wind turbine controllers rely on these systems to maintain optimal operating temperatures, ensuring maximum energy output and reliability. Their role in enabling sustainable energy generation underscores their value in combating climate change.

Versatility Across Sectors

The versatility of liquid cold plates is one of their greatest strengths. They can be tailored to suit applications ranging from small-scale electronics to massive industrial installations. In consumer products like gaming PCs, liquid cold plates provide quiet and efficient cooling, enhancing user experience without compromising performance. Meanwhile, in heavy industries like steel production or chemical processing, they manage heat in furnaces and reactors, improving safety and productivity.

Even in emerging fields like quantum computing, liquid cold plates are proving invaluable. Quantum processors require extremely low temperatures to function correctly, and liquid cooling systems offer the precision and stability needed to achieve these conditions. Their adaptability ensures that they remain at the forefront of technological innovation.

Liquid cold plates exemplify the perfect blend of efficiency, adaptability, and sustainability, addressing the growing demands of modern technology. By delivering precise cooling, supporting green initiatives, and adapting to diverse applications, they are reshaping how we approach thermal management. As industries continue to evolve, liquid cold plates will undoubtedly remain a cornerstone of progress, proving that sometimes the simplest solutions—like harnessing the power of liquid—can have the greatest impact.

English

English русский

русский