In modern automobiles and industrial machinery, engine performance and efficiency are important design considerations. To meet the challenges of high temperatures, many engine systems use a charge air cooler (CAC), a key component that effectively reduces the temperature of the air entering the engine, thereby improving the overall efficiency and performance of the engine.

A charge air cooler is a device used to reduce the temperature of compressed air. It is usually installed in a turbocharger or other type of engine intake system. Before the air is compressed and enters the engine, it must pass through a turbocharger or other supercharging device. Since the temperature of the gas increases significantly during the compression process, the gas needs to be cooled by a charge air cooler to ensure that the air entering the engine is within the ideal temperature range.

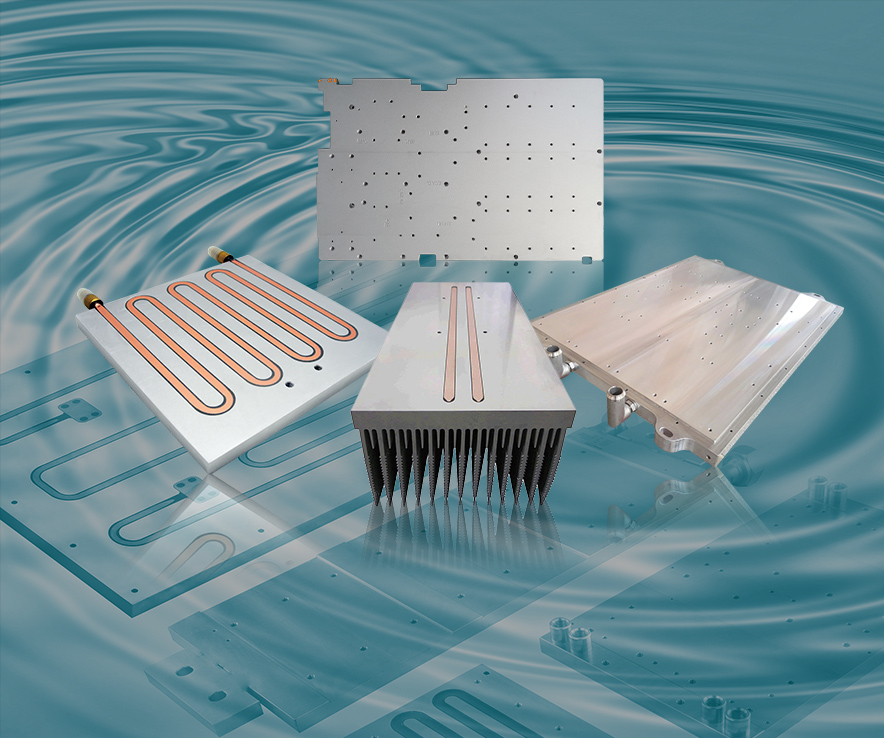

A charge air cooler is usually composed of metal pipes, heat sinks, and cooling media. During operation, air flows through the internal pipes of the cooler, while releasing heat through the external heat sink to reduce the air temperature. This process not only improves the efficiency of the engine, but also reduces engine wear and emissions.

The working principle of the charge air cooler is based on the basic principle of heat exchange. When compressed air is pressurized by a turbocharger or supercharger, its temperature usually rises significantly. At this point, the air needs to pass through a charge air cooler to cool it down to a suitable temperature. The cooler's job is to cool the air by absorbing the heat from the compressed air through an external cooling medium (usually automotive coolant or air).

Charge air coolers accomplish this task through a heat exchange process and usually consist of two parts: a cooling medium and an intake air flow path. The cooling medium exchanges heat with the air through the heat sink, while the intake air flow path is responsible for delivering the cooled air to the engine's intake system. By lowering the temperature of the air, the density of the air increases, allowing more oxygen to enter the engine, improving the engine's combustion efficiency and output power.

The biggest advantage of a charge air cooler is that it improves the thermal efficiency of the engine. The cooled air has a higher density and can provide more oxygen when it enters the engine. This means that the engine can achieve more complete combustion, reduce fuel consumption, and increase power output.

By cooling the intake air, the charge air cooler helps to improve combustion efficiency. A more complete combustion process reduces unburned carbon emissions and reduces the environmental impact of the car or machinery. For modern environmental protection requirements, charge air coolers play an important role in reducing exhaust emissions.

The impact of high temperature on the engine is significant. Excessive temperature not only affects the operating efficiency of the engine, but may also accelerate the wear of engine components. The charge air cooler reduces the heat load of engine components by keeping the intake temperature within a reasonable range, thereby extending the service life of the engine.

In a supercharged engine, the charge air cooler not only reduces the intake temperature, but also improves the response speed of the engine. The cooled air density is larger, and the engine can inhale more air more quickly, thereby improving the engine's instantaneous response ability and enhancing acceleration performance.

The application of charge air coolers is very extensive, especially in the following areas:

In modern automobiles, especially turbocharged engines, charge air coolers are an important component for improving engine performance and fuel efficiency. It is not only suitable for passenger cars, but also widely used in different models such as heavy trucks, commercial vehicles and off-road vehicles.

Many industrial machinery and equipment, such as compressors, generator sets, etc., also use charge air coolers to improve the operating efficiency and performance of the equipment. Especially in industrial scenarios that require high loads or high power, charge air coolers can help equipment maintain optimal working conditions.

Charge air coolers also play a key role in the agricultural field, especially in large agricultural machinery (such as tractors, combine harvesters, etc.). Agricultural machinery often bears heavy loads for a long time when working, so cooling the intake air is important for improving power output and reducing engine failures.

Charge air coolers are also widely used in the engine systems of ships and marine equipment. Ship engines require stable and reliable performance, and charge air coolers help keep the engine running efficiently and reduce maintenance costs.

When choosing a suitable charge air cooler, you need to consider multiple factors:

When choosing a charge air cooler, first consider the temperature of the compressed air and the required cooling effect. Depending on the application, choose the appropriate cooling capacity and efficiency.

Charge air coolers usually need to withstand high temperature and high pressure environments, so their materials must have strong corrosion resistance and heat resistance. Common materials include aluminum alloys and stainless steel.

The installation location and ease of maintenance of the charge air cooler are also factors that need to be considered when choosing. Reasonable installation design can improve the heat dissipation effect, and simple maintenance methods can help reduce long-term operating costs.

As a key component in the supercharged engine system, the charge air cooler plays multiple roles such as improving engine performance, reducing emissions, and extending engine life. With the increasingly stringent environmental regulations and the increasing demand for efficient power systems, the application of charge air coolers will become more extensive and important. Choosing the right charge air cooler can not only improve the operating efficiency of the engine, but also ensure the long-term stability and reliability of the equipment.

English

English русский

русский