The Retrofitting Process:

Retrofitting liquid cold plates into existing medical equipment involves several key steps:

Assessment and Compatibility: Healthcare facilities must first evaluate the compatibility of their existing equipment with liquid cooling systems. Factors such as available space, electrical requirements, and structural integrity must be considered.

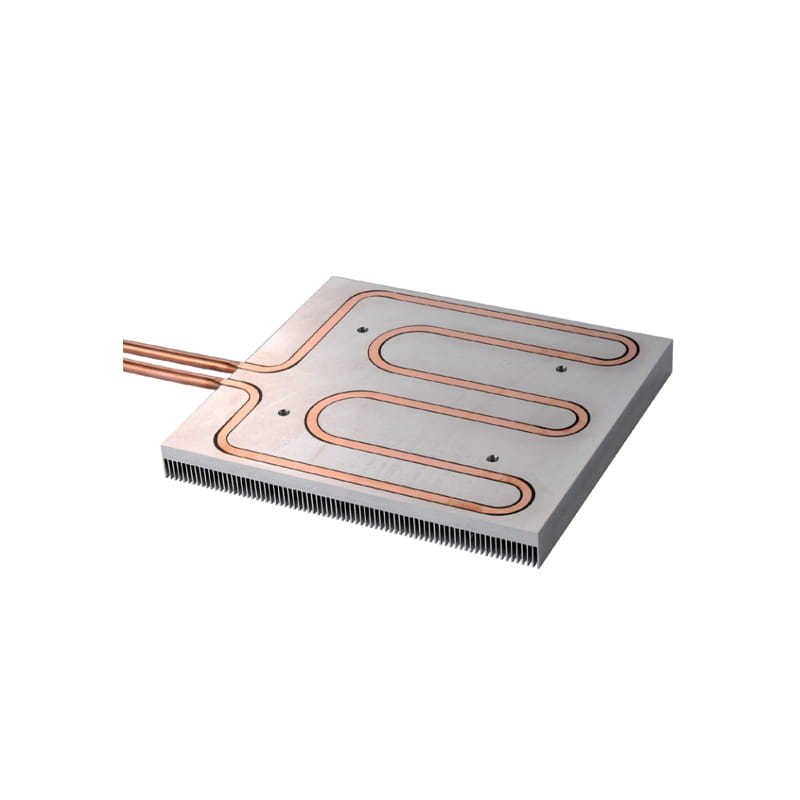

Customization and Design: Medical Equitment Liquid cold plates can often be customized to fit the specific dimensions and requirements of the target equipment. Manufacturers or aftermarket suppliers may offer retrofit kits or bespoke solutions tailored to the needs of individual devices.

Installation and Integration: Professional technicians or manufacturers with expertise in medical device modifications should handle the installation process. Careful integration of liquid cooling components ensures seamless operation and compatibility with existing systems.

Testing and Validation: Following installation, rigorous testing and validation procedures are essential to verify the functionality, safety, and regulatory compliance of the retrofitted equipment. This ensures that patient safety and device performance are not compromised.

Benefits of Retrofitting:

Retrofitting liquid cold plates into existing medical equipment offers a range of compelling benefits:

Enhanced Thermal Management: Liquid cooling provides more efficient heat dissipation compared to traditional air cooling methods, improving temperature regulation and preventing overheating.

Extended Lifespan: By reducing the risk of overheating and component wear, retrofitting liquid cold plates can prolong the operational life of existing medical equipment, reducing the need for premature replacements.

Improved Performance: Stable temperatures are critical for the optimal performance of medical devices such as MRI machines, CT scanners, and medical lasers. Retrofitting liquid cooling ensures consistent operation and enhances device performance.

Energy Efficiency: Liquid cooling systems can be more energy-efficient than air cooling methods, leading to potential energy savings and reduced operating costs over time.

Considerations and Challenges:

While the benefits of retrofitting liquid cold plates are significant, several considerations and challenges must be addressed:

Compatibility: Not all existing medical equipment may be suitable for retrofitting with liquid cooling systems. Compatibility assessments are essential to ensure successful integration without compromising device functionality or safety.

English

English русский

русский