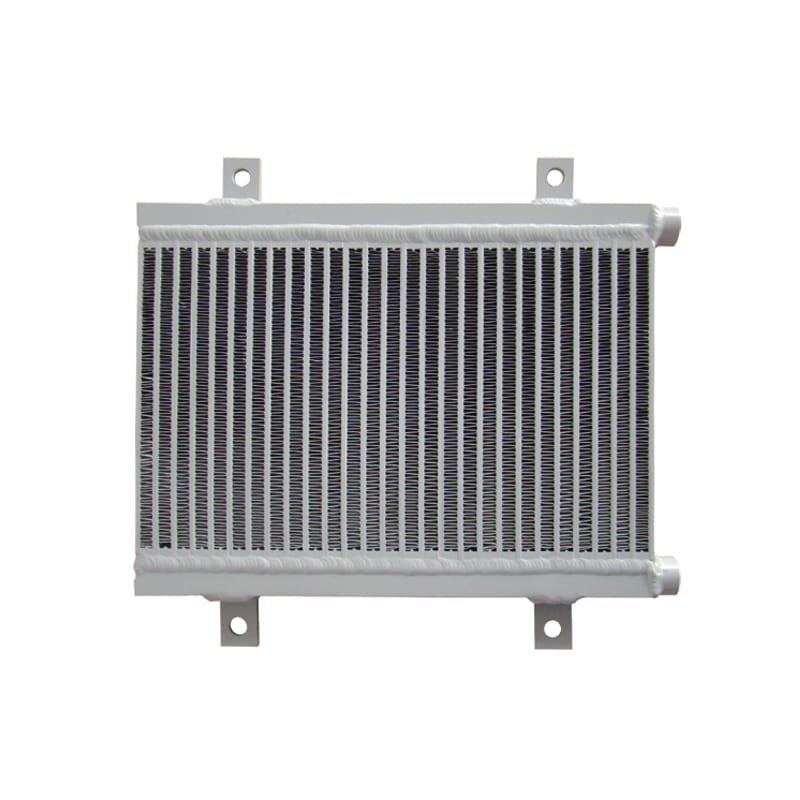

In modern industrial production, heat exchangers are one of the indispensable components. They play a vital role in various processes, such as cooling, heating, condensation and evaporation. As a highly efficient heat exchange device, aluminum slat heat exchangers are favored for their unique advantages.

Aluminum slat heat exchangers are mainly composed of thin slats made of aluminum that are assembled together through specific arrangements and welding techniques. The choice of aluminum material brings several significant advantages to the heat exchanger:

The low density of aluminum makes the entire heat exchanger lighter and easier to install and maintain.

Aluminum has a high thermal conductivity, which means it can transfer heat quickly and increase heat exchange efficiency.

Aluminum forms a dense oxide film on the surface. This film can protect the aluminum slats from corrosion and extend the service life of the equipment.

Aluminum's malleability allows heat exchangers to be customized into different shapes and sizes as needed to suit specific industrial applications.

The working principle of aluminum slat heat exchangers is based on heat conduction and convection. Inside the heat exchanger, fluid flows through channels between the slats, through which heat is transferred from one fluid to the other. This design allows the two fluids to exchange heat without mixing, resulting in efficient thermal energy conversion.

Aluminum slat heat exchangers are widely used in several industrial fields due to their efficient and durable properties:

During chemical reactions, precise temperature control is required, and aluminum slat heat exchangers can provide stable temperature control.

In food processing processes where rapid cooling or heating is required, aluminum slat heat exchangers are ideal due to their rapid heat transfer capabilities.

In air conditioning and refrigeration systems, aluminum slat heat exchangers are used to cool the air and increase energy efficiency.

In power plants, aluminum slat heat exchangers are used to cool generators and transformers, ensuring the normal operation of the equipment.

Aluminum slat heat exchangers play an increasingly important role in modern industry due to their lightweight, high thermal conductivity and corrosion resistance. As technology advances and energy efficiency requirements increase, aluminum slat heat exchangers will continue to play an important role in the field of industrial heat exchange. Through optimized design and material selection, aluminum slat heat exchangers are expected to achieve higher thermal efficiency and longer service life in the future, contributing to industrial energy conservation and sustainable development.

English

English русский

русский