With the rapid development of high-performance electronic devices, power semiconductors, electric vehicles and new energy industries, the thermal management of equipment has become increasingly important. Especially for high-power density systems, traditional air cooling has gradually become difficult to meet the heat dissipation needs. In this context, an efficient and stable heat dissipation technology has gradually come into people's view-Liquid Cold Plates.

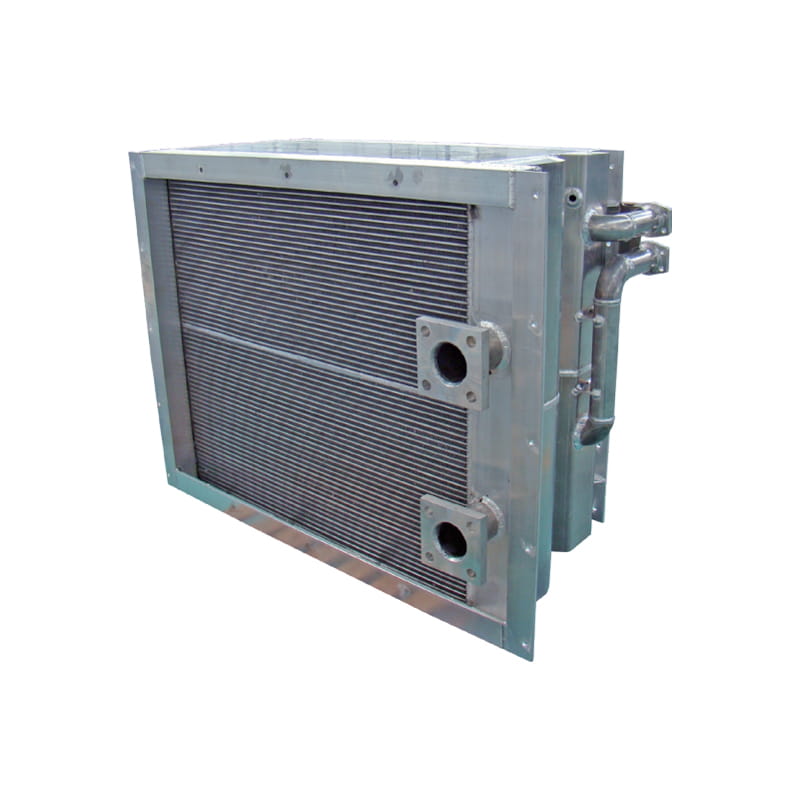

Liquid cold plates are a thermal management component that uses liquid circulation for heat dissipation and is widely used in devices that require efficient heat conduction. They are usually made of high thermal conductivity metals (such as aluminum and copper) and have a flow channel structure inside. When the cooling liquid (such as water or ethylene glycol) flows through the flow channel, it will quickly take away the heat generated by contact with electronic components.

Compared with air cooling systems, liquid cold plates can transfer heat to the liquid faster and more evenly, thereby achieving better heat dissipation performance.

The core advantages of Liquid Cold Plates

Efficient heat dissipation performance

Liquid cold plates can achieve extremely low thermal resistance, which is much more efficient than traditional air cooling or natural cooling methods, especially suitable for scenes with high power density and large heat flux.

Low noise, energy saving and environmental protection

Compared with large fan systems, liquid cold plates are almost noiseless during operation, and due to higher cooling efficiency, they can reduce the overall energy consumption of the system, which is in line with the trend of green energy saving.

Flexible design and easy integration

Liquid cold plates can customize the flow channel and size according to the position and shape of components, which is convenient for integration into different types of equipment, such as servers, power modules, inverters, etc.

Extend equipment life

Good heat dissipation control can reduce the operating temperature of components, slow down the aging rate, and improve the stability and service life of the system.

Typical applications of Liquid Cold Plates

Data centers and servers

With the rise of AI computing and cloud platforms, server power density has risen sharply. Liquid cold plates can effectively dissipate heat for core components such as CPUs and GPUs to ensure stability under high load operation.

Electric vehicles and power batteries

Liquid cold plates are widely used in electric vehicle battery packs, inverters and motor controllers to help control heat distribution and avoid local overheating.

Medical imaging and laser equipment

High-precision equipment such as MRI, electrosurgery equipment, and laser marking machines have extremely high temperature control requirements. Liquid cold plates can provide stable and controllable cooling solutions.

Photovoltaic and energy storage systems

In the field of new energy, liquid cold plates help power conversion modules achieve higher efficiency and longer life, and improve the overall reliability of the system.

Cooling capacity matching requirements: Select appropriate heat flux density design according to the power density of the heat source and the working environment temperature.

Material and corrosion resistance: Copper has stronger thermal conductivity, but the price is high; aluminum has low cost but requires corrosion protection.

Fluid type and compatibility: Ensure the chemical compatibility of liquid cold plate materials and coolants (such as deionized water and ethylene glycol).

Structure and installation method: Select embedded, clamp-on, bolt-on and other structural designs based on actual applications.

In modern high-performance systems, liquid cold plates are gradually becoming the mainstream solution for efficient thermal management. It not only improves system stability, but also promotes the development of electronics, automobiles, medical and other industries towards higher power, higher precision and greener environmental protection. In the future, with the continuous innovation of cooling technology, the application boundaries of liquid cold plates will be continuously expanded, becoming an indispensable "cooling force" behind the technology industry.

English

English русский

русский